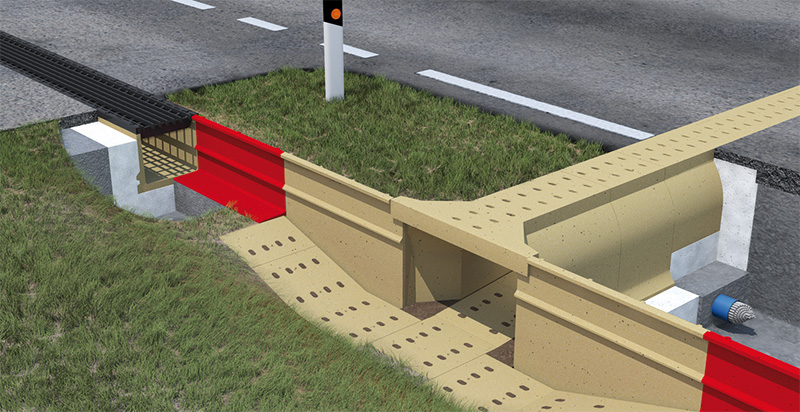

Protection system for amphibians and small animals

The system for the protection of amphibians and small animals is a guiding wall, ACO LEP 100, aimed at preventing amphibians and small animals from entering the road, while allowing road construction at the desired location and volume.

The system consists of a main unit with a 1-meter installation step and additional curved and specially shaped units with an installed length of 0.5 m, so that they are also optimally adapted to complex terrain profiles and terrain. In order to ensure the long-term operation of the amphibian protection system and its stability in the landscape, its installation must comply with the requirements of the manufacturer and the installation must be regularly maintained and cleaned. Recommendations for cleansing times should be clarified with professionals familiar with amphibians and other living beings.

The ACO LEP 100 system allows not only the optimal handling of amphibians by keeping them away from danger areas, but also to carry out the desired earthworks, ensure optimal drainage properties of water, and offers ease of installation and stability.

The barrier footing or base plate inhibits the growth of vegetation, which would otherwise give amphibians the opportunity to climb over the wall.

This is a significant advantage over alternative solutions that are more labor intensive to install and require regular mowing or cleaning of the ground.

Practical benefits of the product

*Drainage properties

The LEP 100 wall module itself has integrated drain holes in the rear of the base, it is also possible to drain at the joints of the footing where the geotextile is applied but is not visible. Surface water naturally drains vertically, significantly improving the stability of embankments and edges.

*Stability

The material used, good drainage ability and low center of gravity provide high stability. The static calculation shows that the edge structure is able to carry a higher moving load (p = 5,0 kN / m2) up to an angle of inclination of 40° (1: 1,2), and in embankments, no further approval of system details is required. In addition, the integrated overlap prevents the parts from shifting.

*Protection of amphibians

Smooth, non-absorbent surfaces with minimal thermal conductivity form an ideal contact zone for amphibians. Double reversal prevents animals from climbing and helps reduce excessive strain on the guide wall. Overlapping hinges ensure optimal interconnection of parts. The properties of the material, i.e. very low coefficient of thermal expansion and high dimensional stability, mean that the possibility of opening joints is minimized. Drainage properties provide good rainwater drainage while keeping moisture in contact surfaces with amphibians. This is a definite advantage, especially for younger amphibians, which need humid conditions the most.

*The main advantage of the ACO LEP 100 guide wall is that the barrier base plate inhibits the growth of vegetation which could otherwise become helpful for amphibians climbing over the wall.

Tunnels:

Safe crossing points, especially for amphibians, depend on a number of factors:

1) It is important that the length of the tunnel is as short as possible

2) The material must not remove moisture from the animals

3) The temperature in the tunnel should be close to the ambient temperature

4) To prevent any disorientation, the components should not contain metal

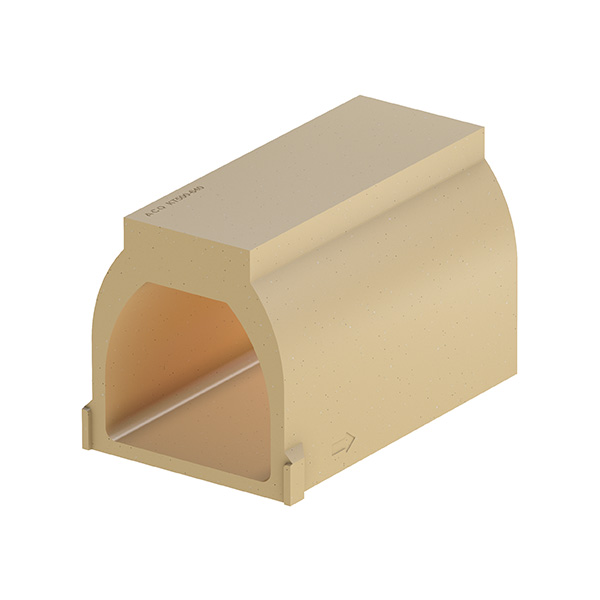

5) The ACO climate tunnel KT 500 meets all these factors, as it is made of polymer concrete.

6) This system can also easily handle high groundwater levels and plugs on roads.

The amphibian, reptiles and small mammals reach the entrance to the tunnel ACO entrance unit following the guide wall system. Thanks to the internal width of 1000 mm and the adjustable height of 500-700 mm, the entrance block can be optimally adapted to the local topography. After installation on the embankment, the surface of the tunnel entrance surface aligns nicely with the upper edges of the side walls.

Climate tunnel with climate gaps or entrance block without slots and the climate tunnel or air conditioning tunnel attached to it form an integrated tunnel environment with slots in the ground. They allow the indoor temperature and light to quickly adapt to local outdoor conditions.

Therefore, they do not affect the dryness of the tunnels and also aim to reduce the air flow through the tunnel.

Climate tunnel elements without a slit shield can be installed on some sections, such as under main road traffic lanes.

Surface layers close to the surface can be only 80 to 200 mm thick.

ACO walls and tunnels are made of polymer concrete, a homogeneous material that is durable, non-absorbent and resistant to various chemicals and salts. The rear connections are sealed due to their interconnected edges.

Unsuitable materials, such as ordinary concrete, metal and silicones, are not used in the manufacture and installation of the products.